Quality Parts Made Easier, Faster

Create high-quality prototypes fast and affordably with REPA. Choose from multiple capabilities, materials, and surface finishes. Get instant quotes and DFM analysis with our lightning-fast quoting platform. Your ideal partner for custom prototyping.

-

20+ manufacturing processes

-

Parts delivered in as fast as 1 day

-

20% off or more affordable pricing

Start Prototyping Today!

Upload your design files for instant price, free DFM analysis.

Drag and drop file or click to upload

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T

Max. file size: ≤15MB

Drop your file here

REPA Manufacture Capability

Explore our comprehensive range of manufacturing solutions tailored to bring your ideas to life with precision and quality.

CNC Machining

Precision-engineered parts with tight tolerances using advanced multi-axis CNC technology for metals and plastics.

Injection Molding

Cost-effective production of complex plastic parts with consistent quality and excellent surface finish.

3D Printing

Rapid prototyping and low-volume production with complex geometries using various materials and technologies.

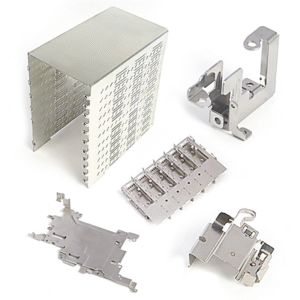

Sheet Metal Fabrication

Custom metal components through cutting, bending, and forming processes with high precision and durability.

Vacuum Casting

Production of small to medium batches of parts with properties similar to production materials for testing and validation.

Mold Making

Expert design and fabrication of high-quality molds for injection molding, leveraging Leo Pai's extensive industry experience.

Manufacturing Process

Our comprehensive manufacturing process ensures quality and precision at every step.

Step 1: Concept & Consultation

Share your product ideas with our sales and engineering teams. We'll collaborate to create initial sketches and refine your plans.

Step 2: 3D Model Design

Our product engineers will transform your concept into a detailed 3D model, visualizing the product and its specifications.

Step 3: Prototyping

Validation Upon 3D model approval, a physical prototype may be created for complex products to verify assembly, functionality, and ergonomics.

Step 4: Mold Design & DFM

Once the prototype is validated, our mold engineers conduct a Design for Manufacturability (DFM) analysis and Mold Flow simulation before finalizing the comprehensive mold design.

Step 5: Injection Mold Making

With the 3D mold design approved, our skilled mold makers commence the precision manufacturing of your injection mold.

Step 6: Sample Approval & Mass Production

Following mold completion, we provide test samples for your approval. Upon confirmation, mass production begins.

Step 7: Finishing & Post-Processing

After mass production, we apply any necessary post-processing finishes, including logo printing, painting, plating, laser engraving, ultrasonic welding, and more.

Step 8: Assembly, Packaging & Delivery

If required, we assemble and package your products to your requirements before arranging efficient and reliable delivery.

Our Advantages

With over 20 years of industry experience, REPAproto delivers excellence in every project, guided by Leo Pai's hands-on expertise.

Fast Turnaround

We deliver high-quality prototypes and molds with industry-leading turnaround times, helping you get to market faster.

Quality Assurance

Every product undergoes rigorous quality control processes to ensure precision, durability, and compliance with international standards.

Expert Consultation

Benefit from Leo Pai's extensive industry knowledge and our team's expertise to optimize your design for manufacturability.

Competitive Pricing

We offer transparent, competitive pricing without compromising on quality, helping you maximize your ROI.

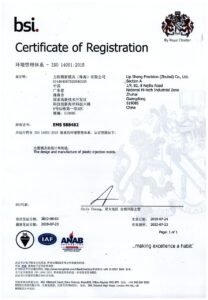

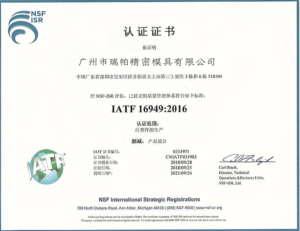

Our Certifications

REPAproto maintains the highest industry standards with internationally recognized certifications.

ISO 9001:2015

Quality Management System certification ensuring consistent, high-quality products and services.

ISO 14001:2015

Environmental Management System certification demonstrating our commitment to sustainability.

IATF 16949:2016

Automotive Quality Management System certification for supplying the automotive industry.

Get Expert Support for Your Project

With over 20 years of experience in mold manufacturing,REPAproto team is ready to help turn your concepts into reality.

Why Choose REPAproto

Industry Expertise

Founded by Leo Pai with hands-on factory experience and deep industry knowledge to guide your project.

Quick Response

We respond to all inquiries within 24 hours and provide detailed quotes within 48 hours.

Dedicated Support

Each client is assigned a dedicated project manager to ensure clear communication throughout your project.